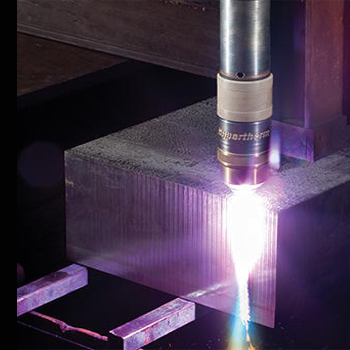

CNC plasma systems are great additions to any workshop because they can deliver high-quality cuts at a relatively low operating cost. While CNC machines are large purchases and there are many factors you may want to consider before buying. By doing the appropriate research you can save yourself as well as your company a great deal of time and money.

The quality of the machine

The most important thing you want to ensure before buying is that you are investing in a high-quality machine.There are a few different things to consider when looking at the quality of a machine.

Design of the machine:

Before deciding on the plasma you want, you should look at the design of the table. Even the smallest factor can affect

the performance of the table. Also, consider for gauge metal cutting a machines roller hold-down feature as there will inevitably be plasma dust that can effect some units. This plasma dust can eventually mix with the oil creating a sludge that can damage your parts.

Servo motors are generally considered to be better than stepper motors. A servo motor can move to a virtually infinite amount of positions within its range of motion and tells the operator where it is at every moment. A stepper motor on the other hand, only has a finite number of positions it can move to and does not provide this feedback for the operator. This creates situations where an operator will tell the stepper to move to a certain area, but because it does not provide feedback, the operator will not know if this movement actually occurred. This becomes a problem if the torch comes into difficulty causing the entire cut to be offset from what the operator planned. Although, servo motors are more expensive than stepper motors, they make up for the cost with the added precision and assurance they offer.

The software that comes with your machine ?

How the machine handles dust and smoke ?

Downdraft:

A downdraft system is a series of skirts around the base of the table along with a fan that sucks the smoke and dust through

the table through a filter. This feature effectively eliminates the smoke and dust although can be anywhere up to 20% of the cost of your machine .

Water table:

A water table is another alternative for containing your dust and smoke. It is essentially a shallow table of water under the cutting surface of the plasma that catches sparks and dust as they fall. The one downside of a water table is that the water can splash on the bottom of the cutting table and cause rust to form. This will require your constant attention to ensure this does not happen. Typically customers use a rust inhibitor so that no rust in the table forms.

Once you have considered all of these factors and more you will be in a much better position to make an informed buying decision. CNC plasma technology can be a large capital outlay which requires the appropriate cost-benefit analysis, will ultimately increase a company’s productivity.